Climate change continues to be one of the greatest challenges of our time. Our industry’s efforts to reduce emissions play a significant role in climate change mitigation. In order to mitigate our impact on the environment and contribute to tackling climate change, we have set a total of four targets for the two time horizons to reduce the intensity of our greenhouse gas emissions.

Marimekko has set science-based short-term emission reduction targets approved by the Science Based Targets initiative (SBTi). By the end of 2030, we are committed to:

• 42.0% reduction in absolute scope 1 and scope 2 greenhouse gas emissions from our own operations compared to 2022 levels.

• 51.6% reduction in scope 3 greenhouse gas emissions in relation to value added (EUR million) compared to the 2022 level.

The target limits include soil-related emissions and removals of bioenergy feedstocks, and they are in line with the goals of the UN Paris Agreement on climate change.

As part of our sustainability strategy, we have also set targets for greenhouse gas emissions. By the end of 2025, we are committed to:

• 50% reduction in logistics GHG emissions (scope 3) per kilogram of transported product from 2018 levels

• 20% reduction in greenhouse gas emissions from textile materials (scope 3) per kilogram of sourced textiles from 2019 levels.

In addition, Marimekko has set a target to reduce greenhouse gas emissions from its own operations (scope 1 and 2) by 40 percent by the end of 2025. This was achieved in 2022. In the future, Marimekko will monitor the progress of its own operations in accordance with the above-mentioned emission reduction target extending to 2030.

The carbon footprint of Marimekko’s value chain

In order to measure our progress against our sustainability targets, we calculate the greenhouse gas emissions from our entire value chain (Scopes 1–3) annually in line with the Greenhouse Gas Protocol standards (GHG Protocol). In 2024, Marimekko’s greenhouse gas emissions were 51,313 tCO2e.

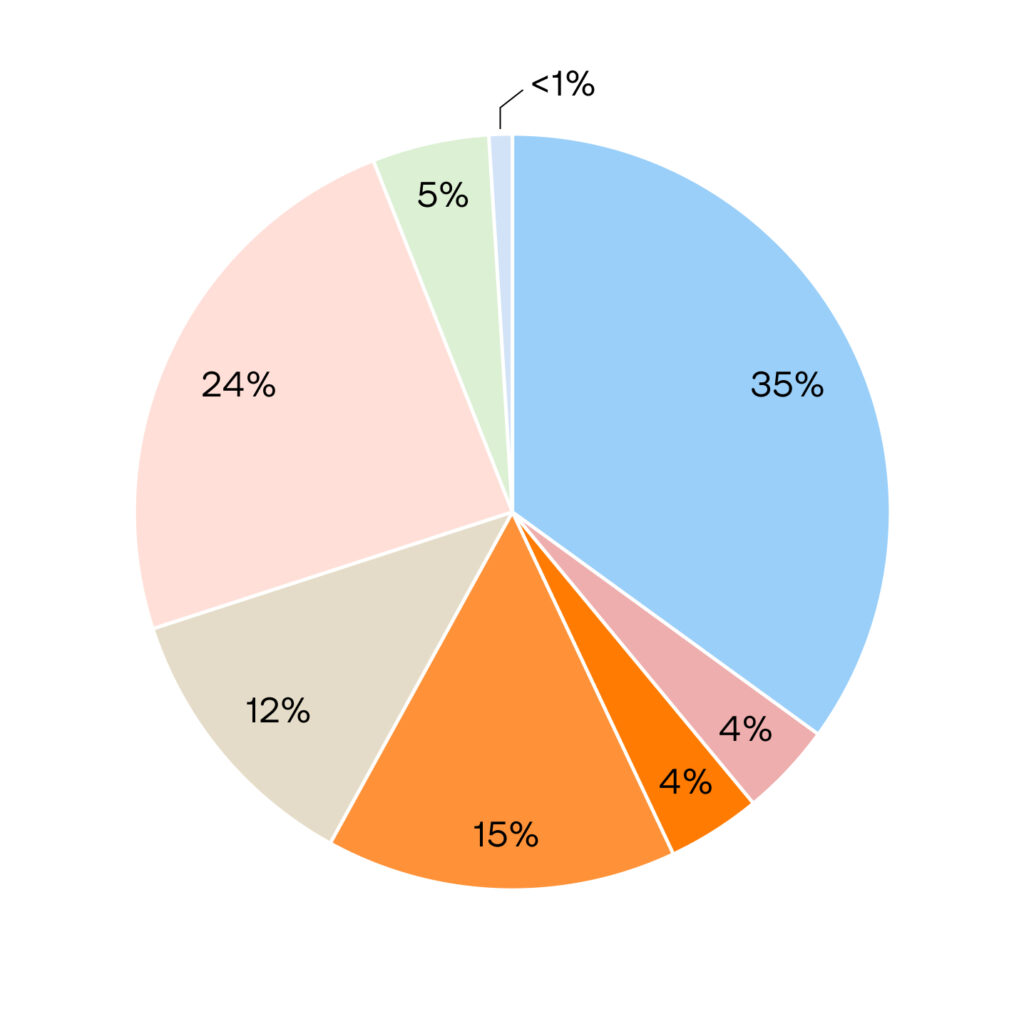

Our calculations since 2019 have shown that the direct emissions from our own facilities and vehicles (Scope 1) and indirect emissions of our purchased energy (Scope 2) represent less than one percent of our emissions, while over 99 percent of our emissions result from other indirect emissions in our value chain (Scope 3). Most of the Scope 3 emissions originate from purchased goods and services, the use of sold products, and logistics.

Scope 1 and 2: Own operations less than 1%

Scope 3: Purchased textiles 35%, Manufacturing of textile products 4%, Purchased ceramics and glass and their manufacturing 4%, Other purchased goods and services 15%, Transportation and distribution 12%, Use of sold products 24%, Other such as business travel and waste 5%

Marimekko’s transition plan for climate change mitigation

We have drawn up a transition plan for climate change mitigation as part of setting science-based emission reduction targets. In the transition plan, which could also be called, for example, a roadmap, we have assessed the effectiveness of various measures to achieve the emission targets we have set. The plan includes the measures already underway and planned to reduce emissions in our own operations or value chain, as well as the estimated emission reduction potential of these measures. In our transition plan, the means to reduce emissions can be divided into four themes: material transition, logistics optimization, transition to renewable energy and other measures.

The measures to achieve our scope 1 and 2 targets for 2030 (-42.0% compared to 2022 levels) are related to the transition to renewable energy, for example by switching all our own leases to renewable electricity globally and by phasing out the use of fossil fuel oil on our leased property. The impact of these measures has been estimated to be medium, i.e. the reduction would be 50–500 tCO2e on an annual basis.

To achieve our Scope 3 target (-51.6% from 2022 levels), the transition plan includes the continuation of material transition, logistics optimization and transition to renewable energy. Of these, there are five measures with a high emission reduction potential, i.e. a reduction of more than 500 tCO2e on an annual basis. These are increasing the shares of organic and recycled cotton, traceable and lower-emission leather and recycled wool in our collections, optimising our logistics routes, especially in Asia, and supporting our contract manufacturers in the energy transition.

In achieving the Scope 3 target, there is a medium-high emission reduction potential by, for example, increasing the share of recycled materials in materials other than cotton and wool in our collections, increasing the share of lower-emission packaging materials, reducing returns in our online store, and taking energy sources into account when selecting new suppliers for our products. However, we have already required our partners to favour renewable energy and strive for emission reductions.

Although a significant part of the greenhouse gas emissions during the entire life cycle of a long-lasting garment are generated by the garment’s care, i.e. washing, drying and ironing, our scope 3 target does not include emissions caused by the use of products. However, we want to support consumers in reducing emissions from use. Therefore, we aim to improve the maintainability and repairability of our products, provide our customers with material-specific care instructions in our care guide, and increase the range of lifecycle services we offer.

Progress in our targets set for end of 2025

Above, we outlined two GHG emission reduction targets for 2025 – how did we progress in 2024?

In 2024, we achieved for the first time our goal of reducing greenhouse gas emissions from textile materials per kilogram of sourced textiles. Greenhouse gas emissions from textile materials decreased by 21% from the base year, while the target for the period 2019–2025 is -20%. The main reasons behind achieving the targets are the determined implementation of Marimekko’s materials strategy, such as increasing the share of organic cotton and recycled materials, the update we made in 2023 to the calculation methodology, the reduction of emission factors and the decrease in the share of wool and leather from the previous year.

In 2024, we fell short of our target set for logistics emissions. Greenhouse gas emissions from logistics per kilogram of transported products decreased by 20% from the base year, while the target for the period 2018–2025 was -50%. The increase in emission intensity compared to the previous year is due to the increase in the share of air freight. In addition, Russia’s invasion of Ukraine in spring 2022 put an end to sea-train combined transports, which are largely faster than ship transports, which further lengthened the lead time for product orders in the supply chain. To avoid possible overproduction, it was also necessary to increase to some extent faster but more emission-intensive air transport .

Marimekko’s material strategy

We want to create items that truly last in use, and thus a key consideration for us when choosing materials is their quality. Through material choices we can also reduce the environmental impacts in our upstream value chain, and therefore we are committed to increasing the share of, e.g., less emission-intense and water consuming materials in our products and packaging.

A key measure in reducing our carbon footprint is the execution of our material strategy. With the material strategy, we aim to increase the use of organic, regenerative, recycled and less emission-intensive materials and reduce the use of conventional materials. The rollout of this material strategy began in the beginning of 2021.

In 2024, the share of recycled materials remained almost at the previous year’s level at 20 percent (21), the share of materials from organic and regenerative farming increased to 39 percent (20) and the share of new innovative materials remained 0 percent (0) of all textile materials purchased. Marimekko classifies the rest of the acquired textile materials as conventional or conventional enhanced materials. A detailed list of Marimekko’s preferred materials can be found here.

As part of the implementation of our material strategy, we are committed to phasing out the use of conventional cotton. In 2024, only 2% of the cotton purchased by Marimekko was conventional cotton (5). 52% was organic cotton (29), 40% was Better Cotton (57) and 6% was recycled cotton (9).

Environmental key figures

| 2024 | 2023 | |

| Energy consumption | ||

| Total energy consumption, MWh | 7,365 | 6,874 |

| Share of renewable energy of total energy consumption, % | 93 | 93 |

| Greenhouse gas emissions | ||

| Total greenhouse gas emissions (Scope 1, 2 ja 3, market-based), tCO2e | 51,313 | 50,323 |

| Direct greenhouse gas emissions (Scope 1), tCO2e | 105 | 124 |

| Indirect greenhouse gas emissions from purchased energy (Scope 2, market-based), tCO2e | 98 | 79 |

| Indirect greenhouse gas emissions from purchased energy (Scope 2, location-based),tCO2e | 274 | 279 |

| Other indirect greenhouse gas emissions (Scope 3), tCO2e | 51,110 | 50,119 |

| Greenhouse gas emissions of textile materials per kg of sourced textiles, kgCO2e/kg | 11.0 | 12.7 |

| Greenhouse gas emissions of logistics per kg of transported product, kgCO2e/kg | 1.7 | 1.5 |

| Waste | ||

| Waste generated from operations, tonnes | 96 | 79 |

| Waste utilized as energy or material, % | 100 | 100 |

| Waste utilized as material, % | 56 | 57 |

| Waste utilized as energy, % | 44 | 43 |

| Water usage | ||

| Total water withdrawal, m3 | 22,432 | 21,422 |

| Total water consumption, m3 | 716 | 670 |

| Water scarcity score of textile materials | 9.8 | 27.8 |

| Purchased textiles | ||

| Share of recycled materials, % | 20 | 21 |

| Share of organic or regenerative materials, % | 39 | 20 |

| Share of conventional enhanced materials, % | 36 | 48 |

| Share of conventional materials, % | 4 | 11 |

| Share of certified wool of all used wool, % | 54 | 67 |

| Share of OEKO-TEX® certified fabrics printed in our own printing factory, % | 48 | 80 |

| Share of unbleached fabrics printed in our own printing factory, % | 20 | 40 |